Devices that perform online measurements in production plants, production lines or on conveyor belts are usually located in very harsh environments. Sound, dust, heat, cold, dirt or humidity are only some of the challenges that such a device has to face.

None of the gas pycnometers available on the market to date is readily suitable for this.

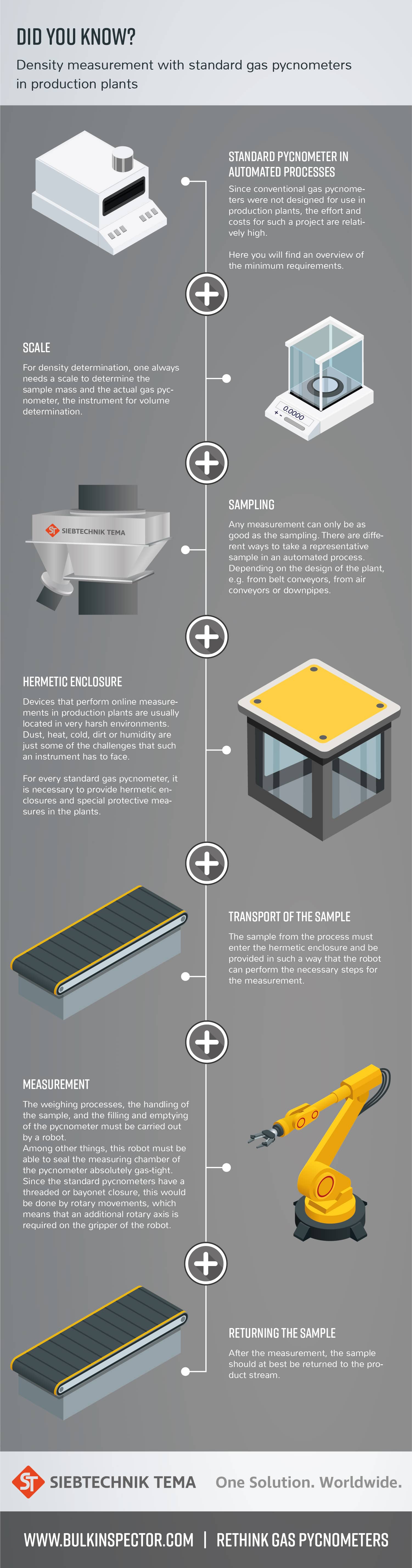

Conventional Pycnometers – High Efforts & Costs

The effort and cost of implementing such a project would be high. For any standard gas pycnometer, it would be necessary to provide hermetic enclosures and special protective measures in the facilities. In addition, the weighing as well as the filling of the pycnometers would have to be done by a robot. Among other things, this robot would have to be able to seal the measuring chamber of the pycnometers absolutely gas-tight. Since the standard pycnometers have a threaded or bayonet closure, this would be done by rotary movements, another hurdle for such a project, because this would mean that an additional rotary axis would have to be integrated on the gripper of the robot.

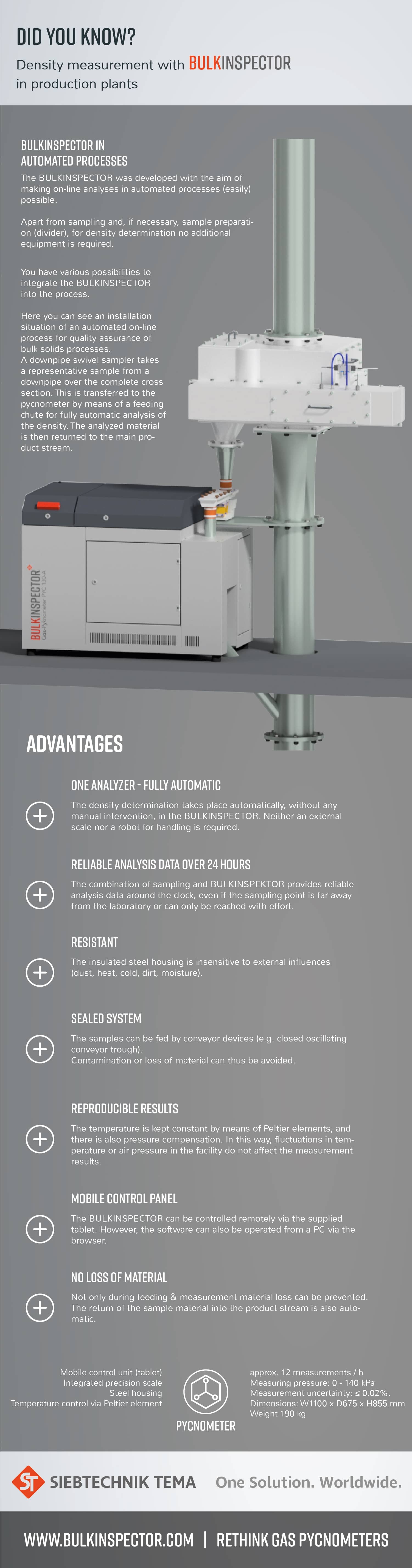

Why are these problems not present with the BULKINSPECTOR?

Since our BULKINSPECTOR is a closed system, all these problems are completely eliminated. Sound, dust, heat, cold, dirt or humidity do not bother it.

The insulated steel housing is largely insensitive to external influences. The samples can be fed by conveyor devices, such as a closed oscillating conveyor trough. In this way, contamination of the sample can be excluded.

Since the weighing also takes place inside the BULKINSPECTOR, foreign influences can be almost excluded here as well. Furthermore, the high-precision weighing cell is less sensitive to vibrations than common standard scales.

The temperature inside the device is kept constant by means of a Peltier element, therefore heat or cold also have no influence on the measuring result, even such values as the constantly changing air pressure do not falsify the measuring result.

Therefore the BULKINSPECTOR gas pycnometer is equally suitable for laboratories as well as rough process conditions.