Why does the quality of an analysis often depend on the person performing it? And why are there certain tasks in laboratories, which often may only be performed by a certain person?

In many cases, the answer is know-how, practice & efficiency.

You need the knowledge of how to proceed and avoid mistakes in general. Routine and good planning of the workflow also help to avoid mistakes and also save time.

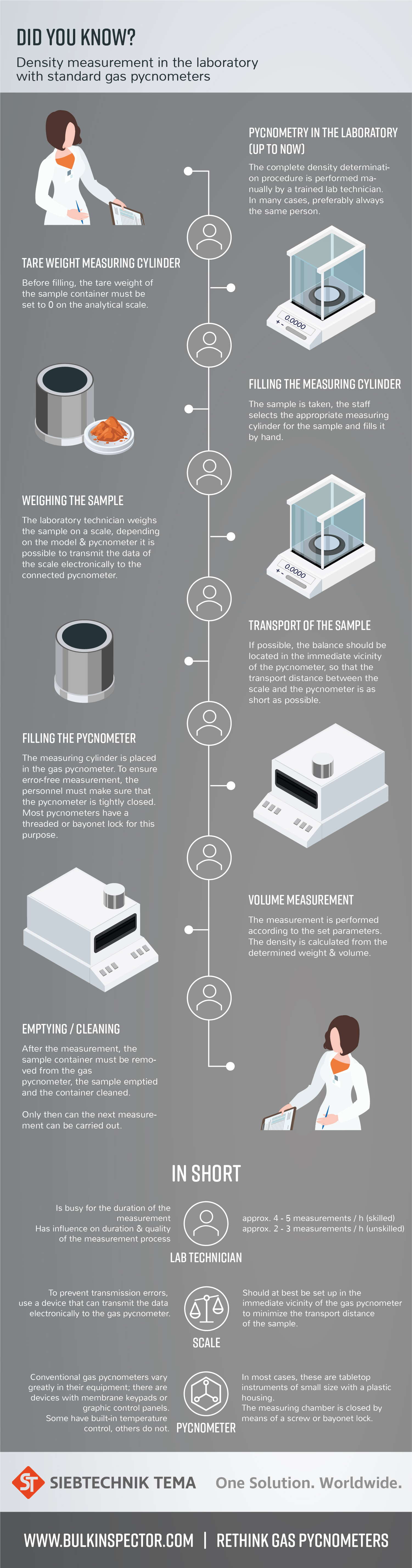

Actually, conventional density determination consists of two individual measurements on two different devices – a scale for determining the sample mass and the actual gas pycnometer, the device for volume determination.

Even the handling between the two devices can cause measurement inaccuracies and even the smallest contamination will falsify the result.

In addition, with a standard gas pycnometer, the laboratory technicians are busy for the entire time of the measurement process.

To better explain the process of conventional density determination and the differences to the BULKINSPECTOR, you will find all necessary information including the common error potentials here.

Avoidable sources of error

The setup of the laboratory

Conventional Pycnometer

To avoid errors in handling and transporting the sample, or even alteration of the sample, it should be ensured that the scale and pycnometer are close to each other. This way the distances are short and the risk is minimized.

Possible risks: Sneezing. The sample could be spilled, or particles could get into it through other processes. Since the sample containers often cannot be labeled, sample mix-up is also conceivable.

BULKINSPECTOR

The complete process of density determination is automated within the BULKINSPECTOR, therefore a proximity to other devices is not necessary.

Temperature control & air pressure

Conventional Pycnometer

Pycnometry is based on pressure measurements of a gas. The thermodynamics of gases require the keeping of exact temperatures and special device measures for thermostatization. Instruments without electronic thermostatization must be operated in rooms with a room temperature that is as constant as possible. This is important in that otherwise there will be seasonal differences in measurement. It is also important that the sample gas is already at the measurement temperature, if possible.

The sample should also be brought to room temperature (actually measurement temperature) and kept under exclusion of air, since the absorption of humidity generally takes place very quickly.

BULKINSPECTOR

The BULKINSPECTOR is a sealed system. The interior of the device is tempered by means of Peltier elements. Also the ambient air pressure does not influence the measuring result.

Handling

Conventional Pycnometer

An often underestimated problem is the sample cup, which can heat up due to contact with the fingers during handling between the scale and the pycnometer. Therefore, thin fabric gloves should be worn if possible. In addition, they prevent contamination of the sample cup with, for example, body fat.

However, because the surface of the sample cup (usually made of aluminum or stainless steel) is smooth, the gloves make handling more difficult. The sample could, for example, slip, fall over or, in the worst case, drop.

BULKINSPECTOR

There is no direct contact with the measuring cups. The BULKINSPECTOR is filled from the outside, the handling inside the device is automated.

Analytical scale

Conventional Pycnometer

To avoid the influence of air currents, always make sure that the doors of the high-precision analytical scale are closed again after the sample has been placed in it. In addition, data transfer to the pycnometer should only take place after sufficient settling time.

If the scale is not electronically connected to the pycnometer, the mass of the sample must be entered manually. Possible transmission mistakes can occur in this case.

BULKINSPECTOR

The weighing process is also automated within the BULKINSPECTOR.

Filling the sample cup

Conventional Pycnometer

The sample cup should be filled to 75% of its volume with the sample, otherwise the gas volume fraction in the measuring cell will be too large compared to the sample volume.

In the case of bulk materials, care must be taken to ensure that the entire sample volume previously generated by separation enters the cup.

A funnel makes the filling work easier for us here.

BULKINSPECTOR

If the sample magazine is used, you can prepare up to 50 samples in advance. After the start, the BULKINSPECTOR will automatically process them one after the other. As there is no need to intervene in the measuring processes, these can also be carried out outside laboratory hours.

Alternatively, you can of course also fill the BULKINSPECTOR individually by hand. For this purpose, the sample is placed in the filling device. Here, too, the measuring cup should be filled to 75% of its volume with the sample.

Pycnometer lock

Conventional Pycnometer

The lock (usually a threaded or bayonet cap) has a considerable influence on the quality of the measurement.

In addition to the temperature errors already mentioned, an improperly fitted lid can lead to a measurement error due to altered measurement volume.

Possible reasons for this: The lid is not properly tightened to the stop (e.g. a dirty thread requires more force to turn) or there are particles between the lid and the measuring cell (contamination of the contact surface).

BULKINSPECTOR

The measuring cell of the BULKINSPECTOR is securely closed via a linear cylinder with force measurement.